|

|

#31 |

|

Senior Member

Join Date: Jun 2011

Location: Northwestern VT

Posts: 224

|

Re: Compression Test

Okay, not sure where to go from here. O_o

I don't know how to post the procedure from the manual but anyway, the acceptable range is from 149 to 199 PSI. Limit is given as 114 PSI. Being as I am quite certain nothing was left in the cylinder, I started the bike up to warm it up. Started right up, no problem at all, valves still pretty loud even after adjusting though not quite as bad as before but still louder than what they had been. Took it out for a spin, about a mile or so. I threaded the homemade adapter in, unhooked the fuel line, opened the throttle and cranked for a few seconds.... Tester seems quite snug and airtight, no air leaks as far as I could tell... So... drum roll.... are you ready? :hide: How in hell could it be... 90 PSI ? :shocked: I don't get it. I would have heard air escaping from the lines if there was a leak in the testing setup. Such a low reading makes no sense at all though. Would the motor even start? It wasn't hard starting at all, not in the slightest. No smoke coming out the exhaust, bike took off as normal no power lag. It certainly didn't run like it was anemic in any way. I couldn't see any kink in the tester hose, again no hissing if air were leaking. I know these motors are very good but if it indeed is running at 90, it sure seems there would be seepage coming from somewhere, like out the exhaust? Any thoughts?

__________________

-- Wayne Login or Register to Remove Ads |

|

|

|

|

|

#32 |

|

Senior Member

Join Date: Dec 2006

Location: Squamish B.C Canada

Posts: 11,409

|

Re: Compression Test

Way, I think you may need to get a proper test rig. Your penny tech equipment is probably giving you a false reading. Sort that out before going in any deeper than needed.

|

|

|

|

|

|

#33 |

|

Senior Member

Join Date: Jun 2011

Location: Northwestern VT

Posts: 224

|

Re: Compression Test

Thanks WW. Yeah, I've been thinking on it and it just doesn't make any sense otherwise. A motor that out of spec is not going to be a pretty sight or sound and it sure as hell isn't going to start right up.

I'll have to get another tester.

__________________

-- Wayne Login or Register to Remove Ads |

|

|

|

|

|

#34 |

|

Senior Member

Join Date: Jun 2011

Location: Northwestern VT

Posts: 224

|

Re: Compression Test

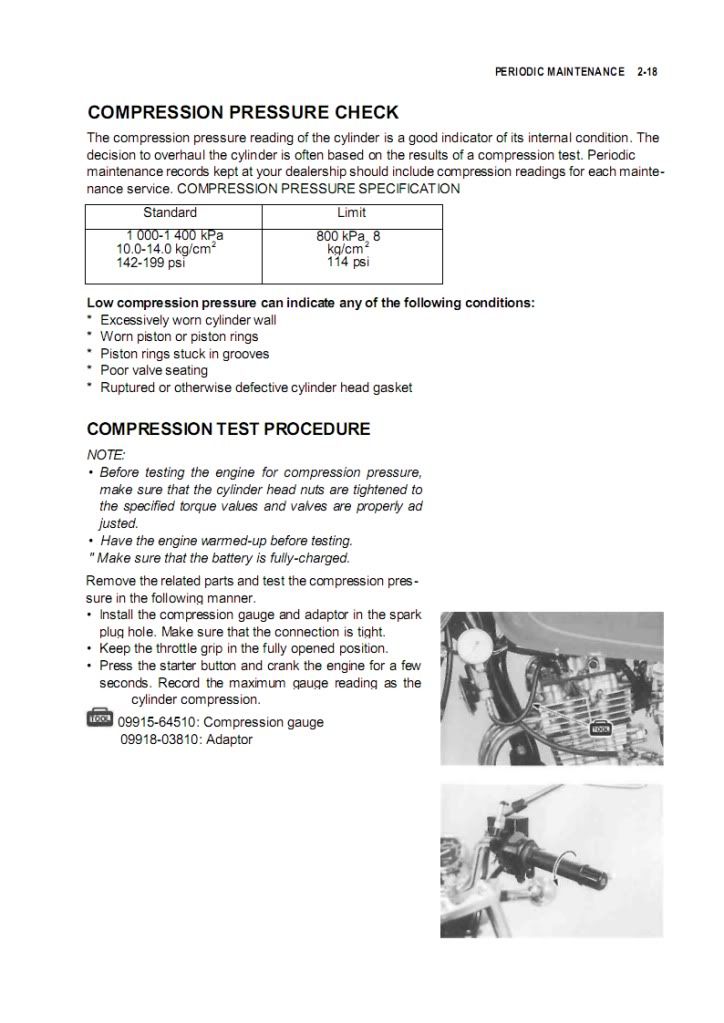

Ok, I at least figured out how to post the procedure in case someone else needs it:

__________________

-- Wayne |

|

|

|

|

|

#35 | |

|

Senior Member

Join Date: Dec 2006

Location: Squamish B.C Canada

Posts: 11,409

|

Re: Compression Test

Quote:

Login or Register to Remove Ads |

|

|

|

|

|

|

#36 |

|

Junior Member

Join Date: Jul 2012

Location: Hungary

Posts: 18

|

Re: Compression Test

Hello,

I made a compression tester..I used an old spark plug for proper connection. After several tests it seems to me, there is no difference if you are using the spark plug's metal gasket for the adapter or simple o-ring. More important to have a non-return valve in between the adapter and indicator gauge. |

|

|

|

|

|

#37 | |

|

Senior Member

Join Date: Oct 2007

Location: HoCo, Maryland

Posts: 1,349

|

Re: Compression Test

Quote:

With the piston at the top, the volume above it is very small so any increase in volume will cause a pressure loss. b) one mile doesn't really warm up the engine, I'd go like 10 miles. A lower engine temperature means you will get a lower pressure reading.

__________________

2005 "Saturn Black", stock + tach |

|

|

|

|

|

|

#38 |

|

Senior Member

Join Date: Jan 2008

Location: Crawfordville, Florida

Posts: 2,853

|

Re: Compression Test

If you are not using a suitable hose in your jury rig that will not expand during the testing, you will not get an accurate pressure reading. Are you using reinforced hoses and a screw-in connector at the plug hole?

|

|

|

|

|

|

#39 |

|

Senior Member

Join Date: Jun 2011

Location: Northwestern VT

Posts: 224

|

Re: Compression Test

I'm not sure if my tester has a check valve in it or not but for that extra cost of getting a check valve, I could probably just save up a few more and get a tester kit with all the adapters.

I didn't think about the volume change. I'm using about 8 inches of reinforced fuel line. It's 3/8 " (9.5mm) and rated to 250 psi. It doesn't look like it's bulging but then again whatever 8" x pi (r2) comes out to be, that would be the additional volume. It's about .88 cu. in. Do you think that would be enough to throw the pressure off by that much? Interesting... I guess it depends on what % volume change that represents. I've got one end of the fuel line threaded onto the existing brass fitting on the tester, secured by a clamp. The other end, I used a 1/4 " nylon connector that I threaded with a M12X1.25 die. I used a large conical faucet washer pressed on as the gasket. It threads in pretty tight as I snugged it with long nose pliers and seems to fit snug against the washer. I don't hear any pressure escaping, the hose doesn't have any noticeable bulge and the compression gauge holds steady at 90 psi, no slow leakage is visible on the gauge. I will try to post a sound recording of the engine running if I can get my stuff together to do it. With the noise of the valve I have no doubt that I have compression loss, but it just has to be higher than what I'm getting.

__________________

-- Wayne |

|

|

|

|

|

#40 |

|

Senior Member

Join Date: Jun 2011

Location: Northwestern VT

Posts: 224

|

Re: Compression Test

Well I ordered an adapter for the tester. Hopefully will be in by the end of the week.

If I was good at money management, I would have just ordered this to begin with and saved time + $10. :roll: If I was really a whiz at money management I would have bought a complete compression tester kit to begin with that had all of the adapters. :poke2: Hopefully, lesson learned for someone else. :whistle:

__________________

-- Wayne |

|

|

|

|

|

|